|

Salt Works History

by Steve Schoenherr

The Salt Works and ponds in 2006.

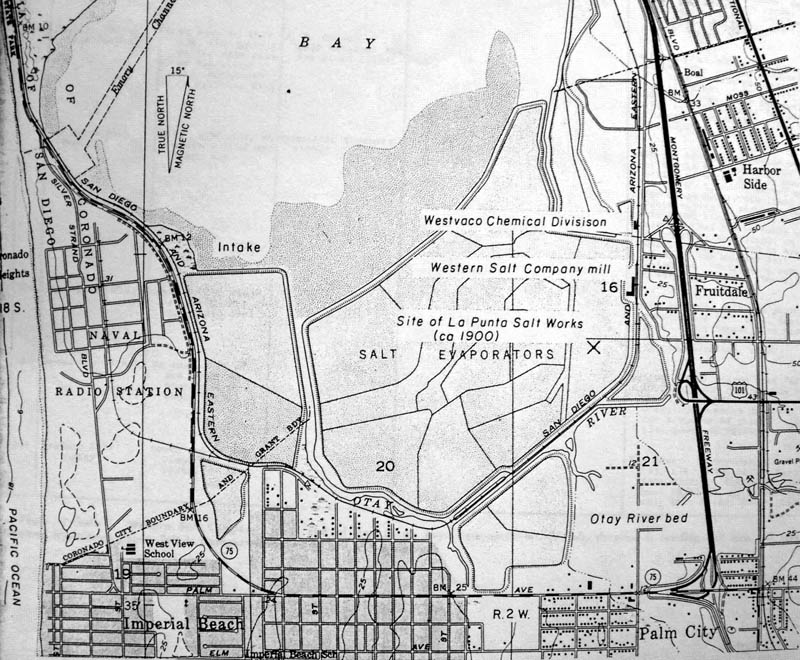

1700 - Salt has long been a commodity in San Diego Bay, as remembered in the autobiography of Kumeyaay elder, Delfina Cuero, who references salt collection by local Native Americans for use as a cure for fish and as a trade good with other tribes (Shipek, 1991, p. 33.). 1782 - Pantoja map of 1782 by Juan Pantoja y Arriaga on the Spanish frigate Princesa. This is the version of the Pantoja map attached to Article 5 of the 1848 Treaty of Guadalupe Hidalgo to define the boundary as starting one league south of the Bay as drawn by Pantoja in 1782. In the South Bay, the map shows the Otay river entering the bay at "Ry Ranc. de la Punta" and the salt marshes at "Est de agua salada." See Maps 1871/04/22 - Josiah Shaffer and James Wadham propose shortly to establish a salt grinding house here. Machinery for that purpose arrived yesterday by the Orizaba. The gentlemen are now making examination with a view to a location for the works. (The San Diego Union, Apr. 22, 1871.) 1871/09/30 - Josiah Shaffer & George Stone making salt near the head of the bay, same quality as Carroll & Vance at their Chollas works, most salt used to cure fish from fishermen on the Lower California coast. (The San Diego Union, Sept. 30, 1871.) 1871/10 - Just as Henry Fenton's start in the construction business came from Elisha Babcock, his foray into the salt business in 1922 also involved Babcock. Henry's business success allowed him to purchase the salt works from Babcock and thus relieve his former boss of a huge financial burden. But the story of salt production in San Diego begins much earlier. In 1871, a 60-acre salt-making plant was operating adjacent to South San Diego Bay with various persons taking charge. In 1888, the La Punta Salt Works, the first formally organized salt company, was owned and operated by brothers Eugene E. and Josiah E. Shaffer with George F. Stone as a partner. Before long, La Punta Salt was producing enough salt to meet the needs of Southern California. Salt was used for preserving food and curing cow hides, for animal feed and for sale to grocers for table use. (Engstrand, 2008.)

La Punta Salt Works was located south of the later Western Salt Company (Weber, 1963, p. 219.)

1872/08/17 - Schaffer and Stone of the La Punta Salt Works have succeeded in making an article of table and dairy salt in no wise inferior to the best in the San Francisco market; have a new trade mark and in a short time bags will be offered with the new brand upon them. (The San Diego Union, Aug. 17, 1872.) 1874/08/11 - La Punta Salt is now on hand and for sale in quantities to suit purchasers by W. W. Stewart & Co., agents for the works. Sacks of all sizes, from three to fifty pounds. ( The San Diego Union, Aug. 11, 1874. ) 1876/12/16 - Frank Kimball at work on the road near the salt works at La Punta. ( Phillips, "Diaries of Frank A. Kimball" )

1888/05/10 - E. E. Shaffer at the Salt Works, has two artesian wells, three and five feet in depth, that are flowing good fresh water a foot above the surface of the ground. Fine water can be found anywhere in this valley from ten to twenty-five feet. ( Otay Press, May 10, 1888. ) 1888/06 - When Babcock & Story purchased the La Punta Salt works with its fresh water spring near the bay, they used dynamite to increase the flow, but the little spring, which had been an oasis for Indian tribes through the years, merely disappeared. John D. Spreckels, of San Francisco, one of the heirs to the huge sugar fortune of his father, Claus Spreckels, became interested in Coronado and purchased a third share of the Babcock & Story Company, then increased his holdings until he was sole owner. He also purchased the Kimball's cement mines on Janal Ranch. ( Phillips, 1956. ) 1888/10/03 - A schooner load of salt is now being shipped from the Otay Salt Works to San Diego every week. ( Otay Press, Oct. 3, 1888. ) 1889/04/11 - E. E. Shaffer commenced letting briny water into his salt vats preparatory for the summer salt harvest. ( Otay Press, Apr. 11, 1889. ) 1889/06/06 - From the Salt Works at the foot of the valley, the sloop Salina, Capt. Christensen, will set sail for San Diego with a cargo of salt June 8, quality equals the best Liverpool brand. ( Otay Press, June 6, 1889. ) 1889/08/22 - Oneonta defeated Otays at Sunday baseball game 22-10 at the salt grounds. ( Otay Press, Aug. 22, 1889. ) 1889/09/12 - Elmer Shaffer and Charles Couts have returned from 3 weeks camping at Jacumba. The boys took an odometer: from Salt Works to Otay, 1.76 mi, from Otay to the following: to Harvey's, 12.34 mi; to Jamul (Lone Pine) 14.2 mi; to Delzura 21.6 mi; to Shecklar's at Cottonwood, 26.8 mi; to Potrero 33.4 mi; to Camp, 43.2 mi; to Adam's Place, 47.8 mi; to Divide, 55.8 mi; to Crabtree, 59.7 mi; to jacumba, 65.8 mi. The boys having regained their health by means of baths and complete rest in this finest locality on earth for those affected with pulmonary troubles, reached home on the 6th. A flock of geese, the first of the season, were seen flying over the bay a few evenings since. Mr. E. Owens is busy clearing his rich valley land bet Main ave and the river. ( Otay Press, Sept. 12, 1889. ) 1889/09/19 - E. E. Shaffer's store sells the bread and baked goods of San Diego pioneer baker Joseph Winters, San Diego Steam Cracker Bakery, 560 Fourth St. ( Otay Press, Sept. 19, 1889. ) 1895/01/08 - Frank Kimball wrote in his diary: "Raining so hard that the stage could not get through from Potrero. Sweetwater full and overflowing. Weirs too small and the water now flowing 2 feet over the full length of the Dam. Water now covers National Avenue from bank to bank of Paradise Valley. DeFord had to secure the foundation of his barley mill with bags of sand. The storm has blown down 20 of my largest olive trees. There is no communication between here and Chula Vista." (Phillips, 1959) 1895/01/29 - Salt Works destroyed by flood waters. ( San Diego Union, Jan. 29, 1895. ) 1899/11/02 - Salt Works owned by E. E. Shaffer and brother Elmer Shaffer, producing 600 tons per year from 4 ponds on 60 acres. (The San Diego Union, Nov. 2, 1899.) 1901 - In 1901, when large salt companies had combined to boost the price of salt, the Klauber Wangenheim Company, wholesale grocers, purchased La Punta Salt. They sold the company after one year of operation to Elisha Babcock, who once again expanded his business interests. On February 12, 1902, Elisha S. Babcock's son Graham organized the Western Salt Company out of La Punta Salt. Original stockholders were Graham Babcock and his wife, Bob Myers Babcock, his father E.S. Babcock, his mother Isabella Babcock, and Clara P. Ingle. Western Salt prospered from the beginning. It was Babcock's objective to expand the existing salt ponds, which were ideal for producing salt, and distribute it via rail to businesses that used salt in their manufacturing process. Graham Babcock was managing Western Salt when he died unexpectedly in April 1908. Eight months later, on December 8, 1908, his widow, Bob Myers Babcock, was installed as a director and was then elected president of Western Salt Company, even though she had little interest in the day-to-day activities of the salt works. A little more than two years later, on April 13, 1911, E. S. Babcock, then president and major stockholder, offered to purchase all the land, improvements and stock of the company, payable six months later in October. With the advent of refrigeration, the demand for salt shifted to industrial uses such as preservation of fish-catches at sea, deicing of roads, and water softening. In March 1910, some additional salt property in a title dispute was quitclaimed to E.S and Bob Myers Babcock. On January 10, 1911, Elisha Babcock replaced his daughter-in-law as president of Western Salt. E. S. Babcock held 1,491 shares. Clara L. Ingle, Raymond B. Talbot, and A. E. Lillicrap held six shares, one share, and one share respectively. (Engsrand, 2008)

1902 - The Western Salt Company was founded by Graham Babcock in 1902 at the southern end of San Diego Bay. Graham was the son of Elisha Spurr Babcock, Jr., who built the Hotel del Coronado in 1888. After the death of Graham, Elisha bought the company in 1911 and expanded its operations. The flood of 1916 almost wiped out the company, but L. M. Drown of the Merchants financed the rebuilding of the salt works, and became profitable by 1918 under Frank Riehle. The bank foreclosed on the property in 1922 after the failure of Elisha Babcock's La Jolla Railway that was supported by loans on the salt works property. Henry G. Fenton bought the company in 1922, paid its loans, and under the management of Neil B. Ditterhaver the company again became successful. ( Chula Vista Historical Society. "Western Salt Company," in Chula Vista, the Early Years. Vol. 2. San Diego CA: Tecolote Publications, 1993, pp. 51-54. ) 1914/07/31 - Elisha Babcock dissolved the salt corporation September 29, 1911, but had no intention of abandoning the salt business. He continued to run the company as a partnership until several years later when, on July 31, 1914, he reorganized Western Salt and appointed a new board of directors. According to a document prepared by Elisha Babcock, he "surrendered the corporation franchise on account of the attitude of the State towards corporations." The State Commission grew more liberal toward corporations and Mr. Babcock reincorporated in August 1914. Babcock was then able to borrow money on behalf of Western Salt to harvest the current crop of salt and purchase new equipment. The new directors paid $100 each to subscribe to the stock. Some time later Babcock purchased the salt works stock from Graham's wife. Between 1912 and 1914, he acquired more land along the south end of San Diego Bay from the Spreckels Company, the Coronado Beach Company, the South San Diego Investment Company, and the Santa Fe Lands Company. Many of these lands were acquired through leases. For example, on Sept. 22, 1911 approximately ninety acres adjacent to Coronado Heights was leased for one dollar per acre per year from the Spreckels Company. Babcock knew little about the harvest and sale of salt, but he made a diligent study of the process. Not only did he correspond with other saltmakers with questions about their operations, he had one of his managers visit several salt works in Northern California. L. M. Drown, General Manager of Western Salt, sent Babcock frequent telegrams from San Francisco about his dealings with Calcutta and Japan as well as with August Schilling, founder of the Arden Salt Company. Babcock learned many aspects of the business and, based on that information, improved the evaporation ponds by building levees. He attempted to expand his market by shipping salt by boat to the Pacific Northwest in competition with San Francisco producers. He also extended the industrial railroad track to access the deep-water channel so that salt could easily be loaded aboard steamers and shipped to distant regions. Babcock developed the sake of bittern water that remained in the vat after the salt had been deposited. Previously, it had been a waste product and an expense, but Babcock was able to sell it for $.50 per ton. Bitterns were used to manufacture magnesium chloride (used for de-icing roads) and Epsom salts. It was sold to the building industry to make magnecite and plastic for floors and drain boards. (Engstrand, 2008.) 1915 - Shigenobu Imamura came to the U.S. in April 1906, right after the San Francisco earthquake, at age 18, was a farmer. He came to San Diego in June 1908, worked at the Theosophical Society on Point Loma for 3 years. "The was no electricity, and no gas. People at the school used lamps. I used to clean the chimneys of those lamps." There was a Japanese tea house and Chop Suey house in the Coronado Tent City. Before the 1915 expo "a number of Japanese had worked in vegetable farming for Chinese farmers. By that time (1915) a large number of Japanese had started farming on their own after two or three years experience working on Chinese farms. . . . People started to get married (around 1915). Some married picture brides. (Usually,) one of the partners in a farming operation would get a certificate from the consul that he was in business and call his wife (from Japan) (She could be a picture bride). The partnership would then split, and the number of (Japanese) families would increase. . . . In 1914 we formed an Agricltural Association. We started to handle our own products. Before we had sold our produce to Italians and Jews. We (Agricultural Association) started to run a produce house. It did very well for a whole." Q: Around 1914 were there many Japanese in the South Bay? A: No. Only those working in the Salt Fields. Even that camp was closed after a year and a half. Mexican workers took over their jobs. The reason why Japanese worked at the salt fields was that there was a salt field at Oakland, and many Japanese worked there, and the fields (both of them) were owned by the Western Salt Companhy. But since there were so many Mexicans here who would work for less most of the Japanese who had worked in the slat fields turned to farming," (Shigenebu Imamura interview, Feb. 12, 1972, and Oct. 24, 1974, by Donald Estes. ) 1916/01/01 - California Ranks Fifth In Salt Production. San Diego Bay Promises To Become Center Of Coast Output. Local Industry Large. Rapid Evaporation Makes Harbor of Sun Particularly Adapted. The production of salt at the West ern Salt Company's big plant on the bay west of Fairfield, a Chula Vista tract, is rapidly increasing each year. California ranks fifth in the production of Salt in the United States a and, although the Industry of extractlng solar-salt from ocean water in this state began at San Francisco in the early days of the gold rush, San Diego is rapidly overtaking its northern rival and bids fair to become the salt producing center of the Pacific coast. Its output for 1916 Is expected to run from 50,0OO to 60,000 tons or one third of the solar-salt output between Mexico and Canada. This increase has bounded rapidly from year to year since 1911, when the total output was 5000 tons. In 1912, it was 8000: In 1913 16,000 and 1914 17,000 tons. A foggy summer in 1914 retarded evaporation and so held down the production a third of what was expected. Within the Iast two years sales of solar-salt have extended from their former markets in Southern California and Western and Central Arizona to Oregon, Washington, Canada and Alaska. Conditions for the manufacture of solar-salt are better in San Diego than anywhere else on the coast. (The San Diego Union, Jan. 1, 1916. ) 1916/01/30 - After the flood, the Western Salt Co. losses consisted of 170 acres of salt ground (which was covered with a deep deposit of silt), 2500 tons of salt, a large quantity of brine in the ponds, and injury to machinery. The total damage was given as $85,500. Fenton-Sumption-Barnes Co. This company operates a gravel-washing plant in Otay Valley, about a mile from San Diego Bay. This plant was a complete loss, for after the flood there not an indication on the surface to show its location. The value of the equipment was $35,000. In addition, the soil was entirely removed from 100 acres of bottom land which had been purchased for about $450 per acre. The business loss was complete from January 27 to May 1. ( McGlashan, 1918. ) 1918 - Western Salt has been official U. S. weather station for 50 years, since govt installed weather gauges in 1908 (1918?) ( Chula Vista Star-News, Apr. 18, 1968. ) 1919 - Felix and Urbana Casillas came from Mexico through El Paso, then to San Diego where he found work at the chemical company next to the works. They first lived in the La Punta adobe, then built their own adobe home at 828 Dorothy Street in 1920s until demolished for I-5 in 1950s. They had 9 children; the 7 brothers including Joseph Casillas, WWII hero, and Armando AY Casillas, 1st hispanic elected to the Chula Vista Elementary School Board in 1966, and Nicolaz Casillas, father of Mary Salas, who served two terms on the Chula Vista City Council and later served two terms in the California Assembly. ( Schoenherr, 2011. )

The two Plymouth Gasoline Locomotives owned and operated by the Western Salt Company. (The San Diego Union, July 1, 1924.)

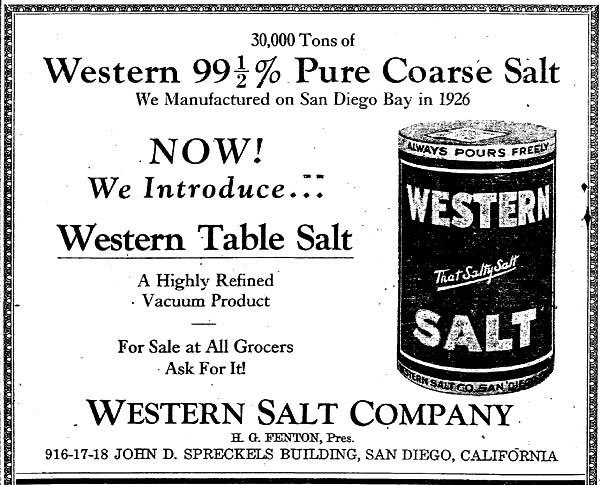

1922/06/01 - Elisha Babcock spent the years 1912 to 1915 improving the salt works, expanding its markets and purchasing new equipment. Then the 1916 flood disaster struck. Henry Fenton arranged with the bank to buy Western Salt on June 1, 1922. The works consisted of 954 acres, including 711 acres, per tax statements from Western Salt; 86 acres purchased from San Diego Land Corporation, 87 acres leased from Spreckels, 70 acres leased from the Harbor Board. During the years 1912 to 1915 that Babcock spent improving the salt works, Henry Fenton was doing well in the gravel, grading and contracting business. He had known Elisha Babcock since his youth at San Pasqual, and had learned about the opportunities in the sand and gravel business during construction of the Zuñiga jetty and Coronado sea wall. Henry had also worked for Babcock on his ranches in Janal and Julian. As a long-time friend of the family, and with his business interests in South Bay lands, Henry Fenton arranged with the bank to buy Western Salt. But Fenton was not the only party competing to purchase the salt works. Businessmen from San Francisco saw what they thought was an easy opportunity to take advantage of a distressed situation. John Stauffer, Sr. of the Stauffer Chemical Company of San Francisco tried to deal through the Bank of Italy to take over Western Salt. Henry, however, was able to offer a better deal to Babcock and his wife. Henry Fenton had a knack for the salt business, both in production and marketing. When he purchased Western Salt on June 1, 1922, the works consisted of 954 acres. All of this land was located at the southernmost point of San Diego Bay, extending from approximately the south line of the City of Chula Vista to the west side of San Diego Bay at Coronado Heights. In 1922, the plant produced about 16,000 tons of salt. Each year thereafter, output increased. Babcock died the year after selling the salt business. After that, Henry made an agreement with Babcock's wife whereby she gave-up her right to 20% of yearly profits in exchange for $250 a month for the rest of her life. she died thirteen years later. (Engstrand, 2008) 1926 - Neil B. Dittenhaver, Superintendent of the Western Salt Company at the time of its purchase, continued to direct the company under Fenton's ownership. An experienced salt producer, he made progress harvesting more salt than before and found ways to improve the purity of the product. A Western Salt Company slogan promised "First in appearance, first in analysis, and first in results obtained." During Fenton's ownership, the company claimed proudly that Western Rewashed Coarse Salt was the best coarse salt obtainable anywhere. It was known throughout the West as "That Salty Salt." In 1926, business opportunities for Fenton grew as he took over the Long Beach Salt Company and the Consolidated Salt Company located at Saltdale in the Mojave Desert. He also assumed control of the Fremont Salt Company located on the same desert lake as Saltdale. These desert salt operations produced a coarse product that was used for water purification and other chemical businesses. Another coastal plant was acquired in Costa Mesa in the Irvine Ranch area at the head of the Newport Slough. Fenton also participated in salt industry activities. He and Aldwyn Hewitt, manager of August Schilling's Arden Salt Company of San Francisco, became business friends and worked together to improve the industry in California. Frank Riehle returned to work for Western Salt when L.M. Drown resigned in March 1919, before Fenton purchased the company in 1922. Riehle served as Secretary- Treasurer of the Board and was responsible for outside sales and business details as well as real estate properties. Two men, Dittenhaver and Riehle, were faithful employees for several decades. Henry Fenton appreciated their expertise and rewarded their loyalty from the very beginning with generous yearly bonuses. Western Salt focused its marketing on industrial uses since table salt was expensive to produce and the demand small. The rock salt harvested in south San Diego by Western Salt was nearly pure enough for table salt but over the years, the salt was sold for water purification, hide tanning, dye making, and pickling. It was sold in blocks to ranches for livestock feed, to fisherman for use in tuna boats to preserve the tuna catch, and to soap manufacturers. A byproduct, magnesium chloride, was used to spread on dirt roads to reduce the dust, and brine shrimp were harvested from the salt ponds and used for tropical fish food. Neil Dittenhaver worked for Western Salt as supervisor of the operation for 45 years, beginning in 1918. He watched the operation increase over the years from 4,000 tons per year to 85,000 tons per year in 1963. He never retired and died at age 78. His son Don Dittenhaver, construction superintendent in 1963, then became manager and served until his retirement. (Engstrand, 2008)

The San Diego Union, March 11, 1927.

1928 - See the La Punta web page for the 1928 aerial photo showing the Salt Works, Fairfield subdivision, and the La Punta adobe. 1930 - Every year for nearly fifty years, down at the southwestern corner of San Diego Bay, a small railroad spent the summer and fall months ferrying loads of salt from Western Salt company's salt harvesting ponds to the company's nearby salt washing complex. The railroad is gone now, a casualty of changing technology. These days Western harvests its salt with powerful, mobile tractors and tractor-drawn carriers-modern equipment. In 1930, though, when the company bought their first locomotive, it and the eight rotary dump cars it pulled were also modern equipment, the products of late nineteenth and early twentieth century American mining technology. The company's superintendent in 1930 was a man named Neil Dittenhaver. His son, Donald, himself a former superintendent at Western Salt, recalls that first locomotive: "That's the first one I drove when I went to work down there. It had the friction wheel drive (an innovation supplanted in later locomotives by clutch and transmission). " In the very early years of the railroad's operation, the company employed up to 120 men, working two shifts, to load the salt and operate the railroad. But soon a machine called a drag line replaced all but seven of the men, and the combination of drag line, two locomotives, sixteen rotary dump cars, and a seven-man crew remained more or less constant until the railroad's demise. Every year, in Mayor June, salt harvesting operations began. One of the company's ten harvesting ponds would be drained of residual brine, leaving a four or five inch layer of salt lying atop a thick salt floor or bottom, as it was called. The salt floor, smooth and shiny as an ice-skating pond, was established to provide a flat, clean harvesting surface beneath each year's crop of salt. A thin layer of loose salt spread over the floor at the end of each harvesting season served as cleavage between the floor and next year's crop, permitting the crop to be harvested without damaging the floor. "They could use the same bottom for years and years," says Don Dittenhaver. "A good bottom would last about twenty, twenty-five years." Once a harvesting pond had been drained, and the solidly caked salt drop had been chiseled into manageable sized chunks, and a five or ten foot channel around the pond's perimeter had been cleared of new salt down to the salt floor that the metal harvesting coop could slide along the floor, then the railroad and the drag line could begin harvesting. "Harvesting" a crop of salt meant picking it up off the pond floor and transporting it to the washing complex, where it would be washed and conveyed to the top of the large stock pile that is so familiar to many South Bay residents. To accomplish the transporting part of the procedure, a permanent narrow gauge (30" wide) track system had been laid, running along the tops of the pond levees and leading back from the ponds to the washer. There were several ways to provide railway access to a pond from the permanent track up on the levee. Most commonly, a ramp would be graded at the corner of the pond, sloping gently down from the levee to the pond, and a joint made in the permanent track there so that the track could be broken. When it came time to harvest the salt from the pond, the permanent tack could be broken-disconnected-at that joint, and the end of the track leading back to the washer would then be bent to curve down onto the ramp toward the pond floor. Portable track-portable enough to be dragged about by a tractor-would be attached to the main line where it enetered the pond and laid, a thirty-foot section at a time, on top of the salt crop for the length of the pond, thus providing a continuous railway from the far end of the pond back to the washer. As the ponds could be quite long, considerable portable track was needed. "Some ponds," says Dittenhaver, "required about 1600 feet of this portable track in order to reach the end of the pond." The salt crop was harvested by steam shovel-like machine called a drag line, a rotating platform mounted on wide Caterpillar tracks and supporting an operator's cab, a powerful gasoline-powered engine, and a long boom. The operator would drive the drag line to the far end of the pond and position it midway between the side of the pond and the portable track. To harvest the salt he would swing the boom out to where the salt had been cleared from the floor, lower the flat-bottomed scoop down to the floor-with the scoop's open end facing back toward him-and then reel the scoop back toward him four or five feet with a econd cable that ran directly from the base of the boom to the scoop. When the scoop had scraped a load of salt into one of the rotary dump car, and when all eight cars of a train were filled with salt, the train driver would head the train on back to the washer. Harvesting was done a "cut" at a time, a cut being a sixty-five foot swath running the length of the pond. (The sixty-five foot width was dictated by the maximum reach of the drag line's boom.) Initially the portable track would be positioned along a line sixty-five feet from one side of the pond and parallel to it. Next, the drag line operator would drive his machine out to the far end of the pond and station it midway between the track and the side of the pond. Then the train would be run out to the far end of the pond, and the drag line would begin picking up salt and loading it into the rotary dump cars. As harvesting proceeded, and the drag line moved down the cut, the track at the far end became unnecessary to harvesting operations, and a two-man crew-tractor driver and laborer-would hook the track to a tractor and haul it over another sixty-five feet, in position for the next cut. The portable track was flexible enough to take on the serpentine curve re ulting from this operation, thus avoiding the need to break the track. The operation was repeated as the drag line moved along the cut, so that by the time one cut was completely harvested, most of the track was in position for the next cut which, like the first, would begin at the far end of the 'pond. The number of cuts required to harvest a pond varied considerably, since the sizes of the ponds ranged from five to twenty-three acres. The train itself consisted of a bright orange (later years sky blue) engine pulling eight equally bright orange rotary dump cars. Engine and cars were all gasoline powered until the 1970 , when the company purchased two diesels, which were about eleven feet long and six feet high at their highest points, the cabs. They weighed from four tons ("Old Grandma," the friction drive engine) to seven tons (the diesels), and they rolled along on four sixteen-inch diameter wheels. They were called, approprately, "dinkies." The rotary dump cars were ten feet long and five feet high. Each was essentially a large open- topped metal box, six feet wide at the top and mounted on a frame that sat directly on the car's axles. The sides of the box sloped down and in, making the box V-shaped. It was so mounted to the frame that it could be tipped over-rotated-to either side to spill out its load of salt: thus the name "rotary" dump car. To tip the box, or hopper, one would have to release two of the four locking levers that ordinarily kept it upright. Releasing one pair of levers would permit the hopper to be tipped to one side; releasing the other pair permitted tipping it to the other side. Each dump car could hold about two and a half tons of salt; that would be a well rounded load. So each eight-car train started back to the washhouse with twenty tons of salt. Traveling at a stately ten to twelve miles per hour, the driver would drive his train up to the washer building and stop. Immediately next to the building-between it and the track-was a forty- foot long pit about three feet wide and five feet deep, with a conveyer chain clanking along at the bottom of it. The driver would position his first four cars alongside the pit, then get out to empty them. To empty a car, he first released the two locking levers on the side of the car away from the pit. This allowed the car's hopper to be tipped toward the pit, with a nudge from the driver. As years passed and the rotating mechanism wore down, more and more nudges became necessary. To help out, the drag line operator would deliberately pile the salt higher on the "pit" side of the car when he loaded it, thereby making it easier for the train driver to tip the hopper over. After unloading the first four cars, the driver would get back in the dinkie and pull the next four cars into position. Then, after waiting until the big conveyer chain had dragged away enough of the first load of salt to make room for the econd, the driver unloaded the econd four car and headed back out to the pond. On the way out, he pulled his train into a siding to make room on the main track for the second train to pass on its way in to the washer with its load of salt. Then he proceeded back to the pond for another load. Operating two trains, the company could harvest 600 tons of salt in one day-fifteen loads per train. So in a five or six month season, roughly 70,000 tons could be taken from the ten harvesting ponds and added to the stock pile. In five decades of railroad operation that translates into 3,500,000 tons, a lot of salt. Of course, the demand for salt fluctuated, equipment sometimes broke down, trains derailed, every year was not a 70,000-ton year. But the railroad did its job and did it well. Now the railroad is gone. It stopped operating in 1978. Most of the rotary dump cars have fallen prey to the scrap-metal dealer's cutting torches. Only four remain, rusting rapidly away in Western's equipment yard across Bay Boulevard from the salt plant. Five of the engines Western purchased over the years are there too, including Old Grandma, the first to go into operation. Their paint has faded and peeled-although the orange and the blue still show under the dust-and the cabs are full of cobwebs. They sit there, the dinkies, on a half- buried strip of track, lined up end to end, waiting for the scrap-metal dealer. But the scrap-metal dealer isn't going to get them. Western Salt is donating all five dinkies and the four remaining dump cars to the California Narrow Gauge Railroad Museum in Phelan, California, where they'll be restored to operating condition. So it could come to pass that someday a visitor to the museum will be able to look down a stretch of track and see a little engine coming toward him pulling a little train of rotary dump cars. (By Olin Hughes, Chula Vista Historical Society. Family, Friends, and Homes. San Diego CA: Tecolote Publications, 1991. )

1935 - Ethyl Corp. had small plant next to Salt Works, processed the runoff liquid from salt process, then added chlorine gas to replace the bromide with chloride, the resulting liquid was pure bromine. ( John Helm interview, July 10, 2010. ) 1936/05/17 - Advertisement for Western Salt "That Salty Salt" Fine and dry. Runs freely. Handy shaker top. Full two pounds, giving you extra servings at less cost. In the Big Blue Carton. At All Piggly Wiggly Stores. ( The San Diego Union, May 17, 1936. ) 1942/05/04 - Western Salt continued its policy of land acquisition and careful management of its property. On May 4, 1942, the company decided to sell its "old 8" suction dredge and barge together with the engine" for $5,000 cash. It also decided to buy several parcels of land totaling 14.5 acres from San Diego and Arizona Eastern Railway near the salt works for $700.00. This included the Otay Wells Spur and other railroad property that it was already using. Western Salt also completed the purchase of 87 acres of the Spreckels Company Coronado Peninsula tidelands for $12,000.00 cash. Western Salt Company's Chula Vista plant, in the meantime, handled the high grade coarse salt business (most of the chemical salt was a less expensive product) and was marketing some 50,000 to 65,000 tons per year from its Chula Vista plant and some 5,000 tons from the Irvine plant (Engstrand, 2008.) 1944 - The Aztec Brewing Company in San Diego generated 332 carloads, but was far outshadowed by Cerveceria de Tecate and affiliated plants at Tecate with 1613 carloads, which would more than double in 1945. The Chula Vista branch was exceedingly important in 1944 with Rohr Aircraft accounting for 1350 carloads, but fewer than 400 in 1945. Packing houses generated 578 cars of citrus and 682 of celery. The salt works on the Coronado branch shipped 1389 cars. ( Robert Hanft, San Diego & Arizona: the Impossible Railroad, 1984, p. 114. )

Salt works 1934

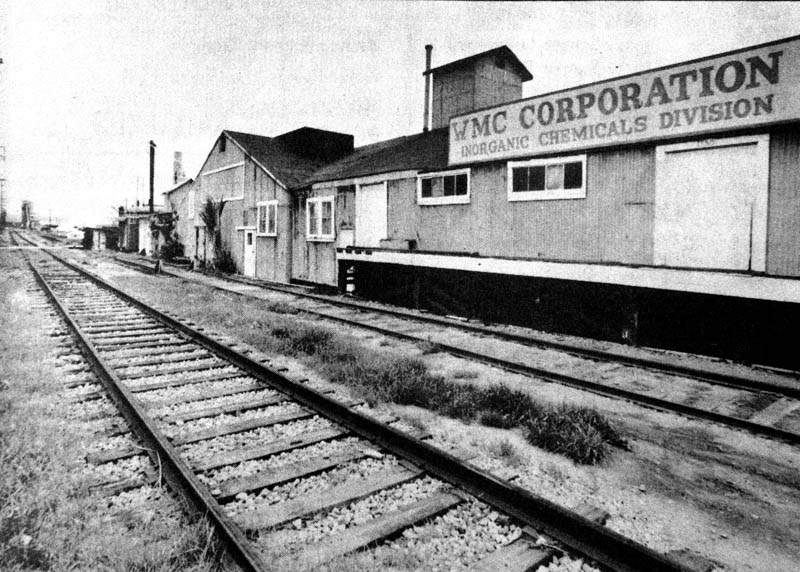

1960 - During the 1960s, tuna fisherman continued to be important customers of Western Salt in Chula Vista. The largest market for industrial salt, however, was the water softener industry. Most of the company's 65,000-ton-per-year production was shipped by truck to retailers of water softeners and de-icing salts for streets and driveways. (Engstrand, 2008) 1982/02/18 - Manufacturing Has Ceased At Western Magnesium Corp. Age and the high cost of fuel have taken their toll on one of the oldest industrial factories in Chula Vista. The Western Magnesium Corp., 1150 Bay Blvd., closed its manufacturing operations last week after about 70 years of producing magnesium chloride in liquid and flake form. The factory's death is partially due to the rising cost of natural gas, its main source of nourishment. Although the plant didn't need many people to keep it running, it needed an abundance of fuel. General manager Milton J. Giorgetta said 40% of the factory's costs were from its fuel bill. Old age also contributed to the demise but Giorgetta said since fuel costs are high and expected to continue upward, rebuilding the plant "wouldn't be worth it." The factory will distribute its product until the supply is gone. Much of the equipment dates back to the plant's early days, The original pump purchased in 1919 for $19.99 and $1.99 shipping cost from New York still brought the water in during the last week of operation. Giorgetta said he couldn't get a modern pump that would work as well so he never replaced it. Now the factory's equipment is being sent to a chemical company in Salt Lake City. While the equipment was at its Bay Blvd. home it would mamrtacture magnesium chloride from brine bought from the neighboring salt company. The product created is used in construction and also as a herbicide and weed killer, Giorgetta said. The plant changed hands many times during its years of operation and Philipp Brothers Chemical in New York owns the operation now. While Bay Blvd. will be losing its oldest industrial plant it also will be losing a distinctive odor. During the manufacture of magnesium chloride the burning of organic material produces a certain scent that some might not miss. "It smells like a burning rag," Giorgetta said. ( The Imperial Beach Star-News, Feb. 18, 1982 )

The Western Magnesium Corp. at 1150 Bay Blvd. (The Imperial Beach Star-News, Feb. 18, 1982.)

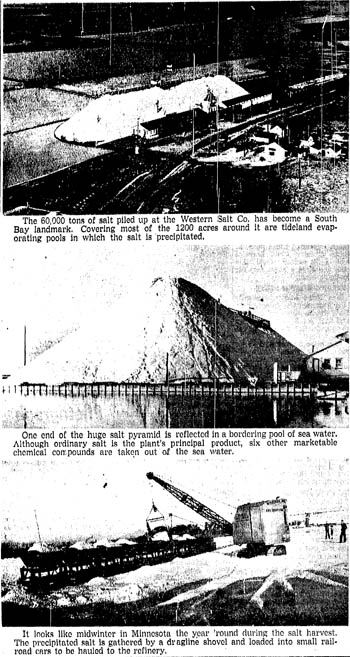

1983/02/20 - Councilman David Malcolm has purchased the Western Magnesium Corp. property at 1159 Bay Blvd., just south of the San Diego Gas & Electric power plant on the city's bayfront. Malcolm and partner Dennis Schmucker, president of USF Liquidating Corp., came to terms with the New York owners of the property Jan. 26, the councilman said. Malcolm said he plans to begin cleaning up the property within 60-90 days so it may be developed. Bill Robens, former deputy city manager who worked as a consultant to the city on the Sander proposal for the bayfront, has been hired to help develop the property, said Malcolm. Malcolm this week cited his purchase of the 4.4-acre plot as the reason he abstained from a Feb. 1 vote. Tuesday the city attorney ruled that he could not abstain from the Feb. 1 vote unless he gave a reason. He then announced he had a possible conflict of interest, and his vote was recorded as an abstention. The Feb. 1 vote was on a general plan amendment requested by James Cappos. Cappos was seeking to locate his Rayne Soft Water plant on the property now used as a city park along the J St. entrance to the bayfront. The City Council rejected Cappos's proposal. Malcolm said he abstained from the vote because of the possibility that Cappos could someday end up on his Western Magnesium property. Though highly unlikely, Malcolm said the city, in the future, couid be forced to condemn property elsewhere on the bayfront to relegate Cappos's business. Cappos is now located at the foot of F St. in an area likely to be designated as open space in the city's forthcoming bayfront plan. Should the city eventually condemn Malcolm's newly-acquired property, Malcolm said he did not want to have voted on a measure that would have helped lead to such a condemnation. "I abstained just for the remotest of possibilities that it would ever come up," said Malcolm. "I am just deathly afraid of any financial disclosures that I should make so I am very careful, I overdisclose because of it." Malcolm, elected to the council last April, is a mortgage banker and is president of his own Suncoast Financial Corp. The 28-year-old councilman said the property, which once housed Western Magnesium's inorganic chemicals operation, has to be cleaned up before development. Much of the 191,000 square feet is currently under water in salt evaporation ponds. When the water is drained, the salt left will have to be dug out. "I took the place as is," said Malcolm. "The clean-up is going to cost $300,000 to half a million." Malcolm declined to reveal the purchase price which he split with Schmucker. He only said it was "a lot of money." Before development, some 28,000 cubic yards of salt will have to be removed, a process which Malcolm described as "very, very expensive." With SDG&E on the north and Western Salt Company's salt-evaporating ponds on the west and south, the site, Malcolm admitted, is "ugly, quite ugly." The smell from stagnant sea water in the ponds is also bad, he said. Malcolm said he would be trying to develop the site for light industrial uses. But the current surplus of such space in the South Bay could pose a problem, he said. (The Imperial Beach Star-News, Feb. 20, 1983.) 1986/05/08 Western Salt, however, did not neglect its salt-producing business. It continued to process about 70,000 tons of salt per year from 1,200 acres of South Bay tidelands. Its stark-white mountain of salt in Chula Vista had even become a special spot for tourists to visit because "from a distance [it] looks like it just got hit with a snow blizzard." (National City News, May 8, 1986.) 1986/11 - Every year for nearly 50 years, down at the southeastern corner of San Diego Bay, a small railroad spent the summer and fall months ferrying loads of salt from Western Company's salt harvesting ponds to the company's nearby salt washing complex. The railroad is gone now, a casualty of changing technology. These days Western harvests its salt with powerful, mobile tractors and tractor-drawn carriers-modern equipment. In 1930, though, when the company bought their first locomotive, the eight rotary dump cars it pulled were also modern equipment, the products of late 19th and early 20th century American mining technology. The company's superintendent in 1930 was a man named Neil Dittenhaver. His son, Donald, himself a former superintendent at Western Salt, recalls that first locomotive: "That's the first one I drove when I went to work down there. It had the friction wheel drive (an innovation supplanted in later locomotives by clutch and transmission). In the very early years of the railroad's operation the company employed up to 120 men, working two shifts, to load the salt and operate the railroad. But soon a machine called a drag line replaced all but seven of the men, and the combination of drag line, two locomotives, sixteen rotary dump cars, and seven man crew remained more or less constant until the railroad's demise. Every year, in May or June, salt harvesting operations began. One of the company's ten harvesting ponds would be drained of residual brine, leaving a four or five inch layer of salt lying atop a thick salt floor, or bottom, as it was called. The salt floor, smooth and shiny as an ice skating pond, was established to provide a flat, clean harvesting surface beneath each year's crop of salt. A thin layer of loose salt spread over the floor at the end of each harvesting season served as cleavage between the floor and next year's crop, permitting the crop to be harvested without damaging the floor. "They could use the same bottom for years and year," says Don Dittenhaver. "A good bottom would last about twenty, twenty-five years." Once a harvesting pond had been drained, and the solidly caked salt crop had been chiseled into manageable sized chunks, and a five or ten foot channel around the pond's perimeter had been cleared of new salt down to the salt floor, so that the metal harvesting scoop could slide along the floor, then the railroad and the drag line could begin harvesting. "Harvesting" a crop of salt meant picking it up off the pond floor and transporting it to the washing complex, where it would be washed and conveyed to the top of the large stock pile that is so familiar to many South Bay residents. To accomplish the transporting part of the procedure, a permanent narrow guage (30" wide) track system had been laid, running along the tops of the pond levees and leading back from the ponds to the washer. There were several ways to provide railway access to a pond from the permanent track up on the levee. Most commonly, a ramp would be graded at the corner of the pond, sloping gently down from the levee to the pond, and a joint made in the permanent track there so that the track could be broken. When it came time to harvest the salt from the pond, the permanent track would be broken, disconnected, at that joint, and the end of the track leading back to the washer would then be bent to curve down onto the ramp toward the pond floor. Portable track, portable enough to be dragged about by a tractor, would be attached to the main line where it entered the pond and laid, a 30-foot section at a time, on top of the salt crop for the length of the pond, thus providing a continuouw railway from the far end of the pond back to the washer. ("The Salt Railroad," By Olin Hughes, Chula Vista Historical Society Bulletin, Nov. 1986. ) 1987/04 - In April 1987 Western Salt donated five locomotives ("dinkies"), eleven rotary dump cars, 2,200 feet of rail and other equipment to the California Narrow Gauge Railroad Museum in northern San Bernardino County. One of the dinkies was a rare 1922 model and most of the rail line had not been used since 1981 when rail equipment was replaced by modern tractors and bottom dump trucks. Narrow gauge track and engines had become extremely rare throughout the United States and the museum planned to put a Western Salt Display Train into operation. (Engstrand, 2008.) 1998/10/15 - On October 15, 1998, the chairman of the San Diego Port District announced that the wetlands that form the southern tip of San Diego Bay would become a 1,400 acre national wildlife refuge developed by the U. S. Fish and Wildlife Service. It would "literally transform San Diego Bay, and marks a significant milestone in the port's commitment to the environment." ( San Diego Union-Tribune, October 15, 1998.) The planned refuge was a shallow section of the bay laced with a series of shallow ponds and low earthen dikes, of which 800 acres was owned and 600 acres leased from the California State Lands Commission by Fenton's Western Salt Company. The amount eventually received by Western Salt for the business and the land owned by the company since 1922, along with the release of the acreage under lease, was $20,500,000. Western made a charitable contribution to the Port District of $4,982,000.84 The wildlife service had been interested in the property since 1979 but had not been able to finalize an agreement. The 600 acres were retained by the California State Lands Commission. By funding the purchase, the Port District was able to use the land for mitigation purposes for the San Diego Airport expansion. The San Diego Port District had previously been criticized for not doing enough to provide a wildlife refuge, so, according to Laura Hunter of the Environmental Health Coalition, it constituted "a stunning move forward in the protection of the bay." Until it signed the agreement, the port could not develop 50 acres of land at the Naval Training Center for airport expansion because it was a nesting site for the California Least Tern, which is protected by both state and federal law. The Port District agreed to pay $1 million to help restore and maintain the Western Salt site and compensate for loss of the Naval Training Center habitat by protecting and enhancing a similar habitat at the Salt Works. The Terns would be protected since salt did not hurt them and there were no humans in the area to pick up the eggs. A number of Western Salt employees continued to operate the salt-production facilities for the port district after the transfer was complete. (San Diego Business Journal, November 30, 1998.) Allen Jones, vice president of Western Salt, commented that the Port District would continue to produce salt at the facility. A formal dedication ceremony of the wildlife refuge, home to more than 560 plant and animal species, took place on June 17, 1999, while an estimated 3,000 or more Terns nested in the nearby wetlands. A group of Double-Crested Cormorants nesting on the boom of a South Bay dredge also witnessed the ceremony. (The San Diego Union-Tribune, June 18, 1999.) 1999/01/30 - The state Lands Commission gave its blessing yesterday to two of the most significant acquisitions in the history of the San Diego Unified Port District: the purchase of salt-producing ponds to create a national wildlife refuge and the acquisition of an electric power plant. Both properties are in south San Diego Bay and, while separate deals, herald profound changes in how the waterfront is used in the South Bay. The Port District will pay $20.5 million to obtain more than 1,400 acres of land owned or leased by Western Salt Co., most of which will be combined with other state land to eventually create a 2,200-acre wildlife refuge. The port, which also operates Lindbergh Field, would pay for the acquisition through its airport funds. Besides shallow water, the area includes eelgrass beds, mud flats, and the diked salt ponds at the south end of San Diego Bay. The high ground of the dikes is critical nesting habitat for at least nine species of ground-nesting birds. The birds include the California least tern, an endangered species, the Western snowy plover, a threatened species, and other terns such as the Caspian, gull-billed and royal terns. In addition, the salt ponds make up one of only two nesting sites for elegant terns in the United States. The deal also allows the port to add more passenger gates when needed at the new wing of Lindbergh Field's Terminal 2. When the port acquired part of the former Naval Training Center, the agency also inherited an established nesting area for the California least tern. That would have prevented the port from fully using its portion of the former Navy base unless the port moved and relocated the terns. The U.S. Fish and Wildlife Service had eyed a portion of Harbor Island as a replacement site, which the Port District wanted to use for a new hotel. Now, the port does not have to worry about least terns tying up either the Naval Training Center or the Harbor Island locations. In addition, a portion of the wildlife preserve could serve as a mitigation bank for the Port District when it undertakes projects that require filling-in of tidal areas. The port will pay $110 million to Sempra Energy to acquire the plant on Chula Vista's waterfront and nearly 200 acres. Duke Energy Power Services would lease the plant from the port for 10 years. Duke's rent would cover the port's issuance of $114 million in lease-revenue bonds. The deal leaves open the possibility of construction of a replacement plant on Chula Vista's waterfront. But Chula Vista residents consider it an eyesore and environmentalists have long decried the pollution it contributes to the air and to the bay. (The San Diego Union-Tribune, Jan 30, 1999. ) 2004/07/01 - Some three decades in the making, the bicycle route encircling the south end of San Diego Bay is nearing completion. The past decade has seen the construction of new bicycle paths along the bay shore in Coronado and Imperial Beach, and work has just been completed on a miniature two-lane bicycle roadway linking National City and Chula Vista. This latter segment of bikeway includes a graceful bridge over the Sweetwater River tidal channel. Using the new link you can piece together a six-plus-mile excursion that visits the bayside waterfront of both cities. A pleasant place to start pedaling is Pepper Park, a public boat-launch facility at the south terminus of Tidelands Avenue in National City. Nearby, at the corner of 32nd Street and Marina Way, you pick up the designated bicycle path (OK for pedestrians, too). Ongoing construction in this area will eventually lead to a small-boat harbor and various commercial venues -- National City's attempt to emulate Chula Vista's developed harbor and bayside park facilities a little farther south. The bicycle path ahead skirts portions of the Sweetwater Marsh National Wildlife Refuge, where moist and not unpleasantly rank odors hint at the biological richness found in shallow tidal channels and uplands covered in salt-tolerant vegetation. The path soon leads to a point under the spaghetti-like ramps of the Interstate 5/State Highway 54 interchange, where signs indicate a junction between one path leading east toward Plaza Bonita, and another path going south toward the Chula Vista Marina. Take the latter, and swoop over the brand-new bridge. Continue curling south, at times separated from I-5's auxiliary ramps by only a low concrete railing, until you reach E Street. A parking lot for Chula Vista Nature Center visitors lies on the right. Go straight on Bay Boulevard, sharing space with the sparse car traffic. Traffic is heavy here only when workers are arriving or departing their workplaces. At Marina Parkway (J Street on the left), turn right to initiate a looping return, using Marina Parkway and Lagoon Drive to get back to Bay Boulevard. The area seems relatively quiet now, but future hotel development along the Chula Vista bay front could change that. If you care to extend your reconnaissance of Chula Vista's shoreline a bit further, make a side trip on Bay Boulevard for a mile south of J Street. You'll pass the natural-gas-fired South Bay electric generating station, and pull up alongside the South Bay Salt Works, where mammoth mountains of raw, granulated salt can be seen. The southernmost extremity of San Diego Bay is one of the few sites in the country where seawater is concentrated and evaporated with the help of solar energy to produce a precipitate of sodium chloride (common table salt). (The San Diego Reader, July 1, 2004. ) 2006 - "Adaptive reuse of historic Salt Works could result in conversion of the building into an interpretive center." ( Bayshore Bikeway Plan for the San Diego Association of Governments. Prepared by: Alta Planning + Design in partnership with Berryman & Henigar. March 17, 2006. ) 2006/11/09 - Coastal Conservancy Recommended Action: Authorization to disburse an amount not to exceed $125,000 to the San Diego Association of Governments (SANDAG) to conduct a study of the area of south San Diego Bay near the mouth of the Otay River to determine optimal alignments of public trails and the feasibility of the possible future use of the Western Salt Works building for interpretive facilities. The planning area includes the 17-acre Western Salt Works property, the mouth of the Otay River and associated flood plain, the San Diego Bay National Wildlife Refuge, 1068 acres of salt production ponds, and a portion of the San Diego Bayshore Bikeway route. The planning area is the locus of four public initiatives, all in different stages of planning or implementation, relating to environmental protection and public access: the San Diego Bayshore Bikeway, the San Diego Bay National Wildlife Refuge, the Otay Valley Regional Park and the Pacific Southwest Railway Museum. In addition to its intrinsic historic and environmental values, the site presents an opportunity to bring together these four interrelated projects to create a public access point where visitors can surround themselves with and gain entrance to the unique history, environment, and recreational opportunities of the communities of South San Diego Bay. The Western Salt Works site has the potential to tie together an access point to the Bayshore Bikeway, a staging area and trailhead for the Otay Valley Regional Park (OVRP), an interpretive center for the San Diego Bay National Wildlife Refuge (SDNWR), and a destination along an excursion train from historic Santa Fe Depot and Museum in National City. (Western Salt Works Site Assessment, 2006.) 2008/04/21 - In 2001, Carrie Gregory, an EDAW staff archaeologist, and Angie Gustafson, an EDAW architectural historian, wrote the Historic Resource Evaluation for Western Salt Works. The authors indicated that nine of the fifteen buildings were over fifty years old and were potential historic contributors to a National Register site. These nine buildings were listed as follows: the Main Processing Plant (ca. 1916-1920, with an addition in 1949); the Pump House (1916); the Electrical Building (ca. 1916-1920); the Generator Building (ca. 1916-1920); the Maintenance Building (1916-1920); the Compressor Building (ca. 1916-1920); the Salt Ponds and Levees (ca. 1916); the Floating Dredge (1924); and the Narrow-Gauge Rail Line (ca. 1916). The most significant of these potentially historic buildings is the Main Processing Plant. Each of the buildings on the Western Salt Company Salt Works property served a purpose that ultimately resulted in a very marketable commodity. The Western Salt Company built the current Main Processing Plant after the 1916 flood. It is a rectangular wood framed building, oriented north to south, and raised approximately 2'- 6" on a concrete foundation. The exterior walls are wood framed and are clad with horizontal wood lap siding. Timber trusses support the gable roof structure which is sheathed with plywood and asphalt roofing. This roofing replaced the original corrugated sheet metal roof. On the east façade, only one of the original loading dock openings remain. The other openings have been infilled with wood framed walls and vertical wood siding. The post-and-beam tower is also supported on a raised concrete slab and is located at the south end of the original structure. The six-story tower reportly once housed an elevator that has been removed. Horizontal wood lap siding covers the wood framed walls and the multiple shed roofs are covered with asphalt shingles. The tower contains rectangular single-lite windows on all sides. Many of them have been boarded-up with plywood. The main conveyor is not historic and enters the top of the tower at the north façade. The processing plant was expanded in 1949 with another storage wing extending to the west creating an "L"-shaped structure. This second storage section connects to the tower and is also elevated approximately 2'-6" on a concrete slab. The Western Salt Works Company has operated as a solar salt processing plant for a century. The Company made a significant contribution to the entire solar salt industry during the period of 1916 to 1949. The Main Processing Plant and the other historic buildings on the Western Salt Works Company property were instrumental to the process of commercial solar salt production that occurred during the early-to-mid twentieth century. In regards to the Main Processing Plant building, it is clearly an extremely rare example of a solar salt processing plant. It is the only one of its kind found in San Diego County. The Main Processing Plant and the Western Salt Works Company property in general are landmarks of the early industrial development of San Diego Bay, and the broader history of California's solar salt industry. ( Salt Works Site Assessment and Draft Vision Plan, 2008, pp. 10-14. ) 2008/04/21 - Executive Summary: The history of salt production in the San Diego Bay dates back thousands of years, to when the native Kumeyaay people found the south bay to be a rich resource and an important gathering place. More recently, commercial salt production in San Diego Bay dates back to the mid 1850s, with the earliest recorded salt plant established in 1871. Since that time, commercial salt production has been a steady and important influence on the south San Diego Bay environment. The salt ponds encompass over 2000 acres of San Diego Bay. Through a process that has been described as a blend of agriculture and wine making, salinity levels are manipulated to steadily higher salinity as water moves from the western ponds to the east. The salt ponds have contributed to an important natural resource, attracting large numbers of migratory and wintering birds. The high saline waters created by the evaporative salt production technique support several species of brine invertebrates that are preyed upon by a variety of birds, and the salt pond levees provide important nesting habitat for several species of seabirds. Currently all of the salt ponds are part of the San Diego National Wildlife Refuge. The Salt Works property is owned by the Airport Authority who leases the land to Western Salt Works. The Western Salt Company Salt Works is an eligible historic resource as determined by the Historic Resource Evaluation Report prepared by EDAW in 2001. The Salt Works buildings are considered historically significant and have been deemed eligible for the National Register of Historic Places and the California Register of Historical Resources. In the future, as the U.S. Fish and Wildlife Service begins to restore the salt ponds to a natural state, the Salt Works site may provide a unique opportunity for public access, education, and recreation near the San Diego Bay. Adjacent to the San Diego Bay National Wildlife Refuge (Refuge), the site could provide public exposure to this valuable natural resource. Because the future of salt production and land ownership of the Salt Works site is uncertain at this time, several alternatives have been developed to allow flexibility for the future use of the site. Alternatives range from complete public use of the site in Alternatives A and B, to providing public access over a portion of the site with continued salt production in Alternative C, to minimal public use with continued salt production in Alternative D. All Alternatives provide a greenway along Bay Boulevard that could accommodate bicyclists and pedestrians, and a trail linkage to the future loop trail that U.S. Fish and Wildlife Service (USFWS) proposes just northwest of the site. Undergrounding of the overhead power lines would provide adequate space for a greenway, while keeping open the option of a future rail linkage. Alternatives A, B, and C include an interpretive center, areas of habitat creation, interpretive trails, a boardwalk, and a parking lot/staging area sized appropriately for the proposed uses. The Pacific Southwest Railway Museum Association is a non-profit educational organization dedicated to the preservation and interpretation of railroads as they existed in the Pacific Southwest. The association operates programs that address the historical, social, economic and technical impact of railroading with emphasis on the railroads of San Diego County. As it relates to the Salt Works site, the association envisions a historic excursion train that would ultimately run from the Santa Fe Depot in National City to a southern terminus at the Salt ( Salt Works Site Assessment and Draft Vision Plan, 2008, pp. 4-7. ) 2008/05/10 - A regional government agency offered a bright view of what the future could hold at a South Bay site that houses one of the oldest salt works operations in California. Dozens of citizens and representatives of city, county and federal agencies with a stake in plans to revitalize the South Bay Salt Works site offered their views at a forum this week [May 6]. A representative of the San Diego Association of Governments presented several options for what could be done at the site. The ideas included an interpretive center for the San Diego Bay National Wildlife Refuge, an access point for the Bayshore Bikeway, a trail head and staging area for the Otay Valley Regional Park, a destination for an excursion train and creation of habitat. Two of the plans allowed for joint use with the plant. But Andrew Yuen, a deputy field supervisor for the U.S. Fish and Wildlife Service who attended the meeting, said plans for the long-term restoration of south San Diego Bay doesn't involve having a salt plant. "The full implementation is going to take a lot of time and more funding than we currently have available," Yuen said. "At the point where we implement the entire full restoration, there wouldn't be a salt operation." This was not good news for Warren Dodd, a representative of South Bay Salt Works, which in 1999 took over the salt operation from the original operator, the Western Salt Co. "The only reason we exist as a salt production facility is because Fish and Wildlife wants us there, and that is because we enhance the habitat. We are the food source and a major stop for the migratory birds," said Dodd, who was at the meeting. "So if Fish and Wildlife wants us to continue, we will continue. If Fish and Wildlife makes a determination and it has an alternative, we will stop at that point." The salt works site has been in operation since the 1870s. By the late 1950s, it became the state's second-largest producer of salt from seawater, after plants in San Francisco. County Supervisor Greg Cox, who heads the effort to upgrade the site, said no decisions have been made yet. The Fish and Wildlife Service has completed its Comprehensive Conservation Plan for the area for the next 15 years, Cox said. The California Coastal Conservancy provided a $125,000 grant to SANDAG, and $61,120 has been spent for design work so far. The final plan is expected to be completed by September. (The San Diego Union-Tribune, May 10, 2008. ) 2012 - The Western Salt Company Salt Works has been in continuous operation since 1916 and retains integrity of design, function, and setting. The Western Salt Company is eligible to the National Register of Historic Places because it has played an important role in the solar salt industry in California. The plant produced up to 10% of California's salt by the 1930s. The property is also significant because the Salt Works embodies the distinctive characteristics of a solar salt processing facility. Distinctive landscape qualities represented by the Western Salt Company Salt Works have changed little from the 1916 operation. ( Historic American Landscapes Survey, Western Salt Company Salt Works, HALS No. CA-67, 2012. ) 2014/02/19 - Gene Mullenix has managed the Salt Works since 1969, was brought in by Dittenhauer son. The 17-acre property of the South Bay Salt Works (name replaced Western Salt) was annexed by City of San Diego ca 1956 but has a Chula Vista address (1470 Bay Blvd., CV 91911). It is owned by Lindbergh Field, in a deal with the Port Authority, and operates under a permit with U. S. Fish and Wildlife. The airport will soon sell the 17-acre property to SDG&E who will give it to Fish and Wildlife in another mitigation deal. The current office and tower buildings were built ca 1954, replacing the original tower and sheds of Western Salt built in 1922. The 3 buildings across the street are older, perhaps dating from 1922, were once the power generation shed, the blacksmith shed, and the large tool shed that once had overhead power train and pulleys. Fish and Wildlife need the salt ponds to continue working, moving water into the ponds, to prevent the salt from killing the birds, and to keep available brine shrimp that the birds feed on. ( Gene Mullenix interview, Feb. 19, 2014, at the Salt Works. )

Port of San Diego Restoration & Enhancement Project (Maher, 2012)

SOURCES:

|

||||||||||||

|

This web page was created May 11, 2017, and revised Sept. 21, 2017, by Steve Schoenherr for the South Bay Historical Society | Copyright © 2017

|